Production Capacity

Home ❯ Production Capacity

Xujohn has a complete production line and mature production technology. Strong production capacity allows us to meet most of our customers’ production needs. Meet customer demand for delivery time and deliver on time at the same time.

Xujohn is mainly composed of two parts: factory and marketing center. The marketing headquarters mainly deals with the content of docking orders with customers, including the selection of order negotiation formula and product packaging design. The production base is mainly responsible for R&D and production. The current production base is in Huangpu District, Guangzhou, covering an area of 20,000 square meters.

In the future, our production focus will be shifted to Chongqing. At present, we have purchased 70,000 square meters of industrial and in Chongqing. It is expected that the construction and production will be completed before 2025, and the production capacity will be more than three times that of the current one by then, which can meet the various individual needs of customers.

Xujohn are equipped with automated equipment in every link, without manual involvement, which greatly improves our production efficiency. During the COVID-19 pandemic, investment in automated production lines can greatly improve product safety and provide customers with the safest and highest quality products. The automation equipment covers a series of processes from the acquisition and screening of raw materials, the ratio of raw materials, emulsification and caning, etc.

Emulsification equipment

Our emulsification equipment is the most advanced in the industry. Our vacuum homogenizing emulsifying unit is imported from Japan. Good production equipment enables us to realize automated production, refined production, and standardized production. Perfectly realize full automation of production and standardization of production specifications. Vacuum and homogenize the product during the emulsification process to make the product shine with the best brightness, to ensure uniform product quality, safety and reduce pollution.

Water treatment equipment

Water plays an important role in our production, so the selection of water production equipment is very important to us. Our water production equipment uses the most advanced American Dow reverse osmosis RO membrane plus EDI combination. The RO membrane and the purified water processed by EDI have a conductivity of 1 or less, which guarantees the best quality of the product.

Hand and foot mask production line

The introduction

of Germany’s fully automated hand-foot film manufacturing equipment, the use of

automatic tension control system, stable and durable hot plate welding, the

panel is hardened, PLC micro-computer control, photoelectric detection, from

raw materials to finished products, the production capacity is up to 200,000

pairs / day. The automatic membrane leak detection function can check each film

cloth in the air pressure compensation mode, and quickly calibrate to ensure

that each opponent’s foot film is properly sealed; independent pressure

increasing and controlling treatment ensures that the film cloth has no back

pressure during transmission. Always provide higher precision.

Facial mask production line

The equipment on the mask production line has been fully automated. Automated facial mask machines imported from Germany, which can make automated mask sheet folding, automatic bagging, bag opening, metering filling, and sealing operations. The whole process is in accordance with ISO22716 good manufacturing practices. The equipment is stable, efficient, and accurate with automatic weighing, sorting, and inspecting system to prevent empty bag, pouch not open, or serums not filling.

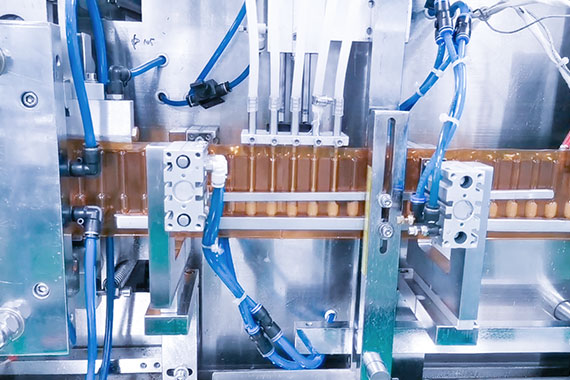

AMP production line

Strictest sterility one process finish production, maximize to keep the activity of products. Our AMP equipment specially designed for cosmetics; the equipment adopts a modular design. The material utilization rate can reach more than 95%. The production capacity can reach 100,000 pcs/day. Two or more materials can be filled simultaneously.

Collagen mask production line

The collagen mask can be automatically produced from emulsification, filling, cooling, vacuuming, testing, and sealing. The daily capacity of a collagen face mask is 200,000 units and 600,000 units for collagen eye masks. At the beginning of the production process, hydro collagen such as silica gel and agar combined with other nutritional ingredients are added into the emulsification machine to make a high-quality collagen mask, which does not require non-woven fabric as a medium. It’s the key process of collagen mask production. The machines of the materials used are imported from Europe and the USA. All the materials we measured will need to be mixed and emulsified under a certain temperature in vacuum conditions. Then the liquid material will go through the clean tube to be injected into the trays of collagen masks. After cooling down, a transparent crystal collagen mask is finished. All processes are automatically completed at one time.

Automatic hydrogel mask production line

The automatic hydrogel mask production line adopts advanced second-generation technology to ensure that all processes such as temperature control of the material, feeding control, film thickness adjustment, rapidly cooling and forming, die-cutting is realized through a microcomputer. Perform control, photoelectric detection, and thickness monitoring are fully controlled by the computer which makes all production processes from the material to the completion of the product to be realized without manual intervention. The production efficiency is increased by 100% compared with the first-generation machine, Besides, the quality stability is improved, with the yield rate increasing to 99.9%. The production capacity is up to 210,000 pairs/day.